How to Bend Aluminum Composite Panel ?

Bending ACPs allows you to achieve unique designs and create visually striking structures. In this article, we will explore the process of bending aluminum composite panels, discuss the methods, tools, and equipment required, and provide a step-by-step guide to help you master this technique.

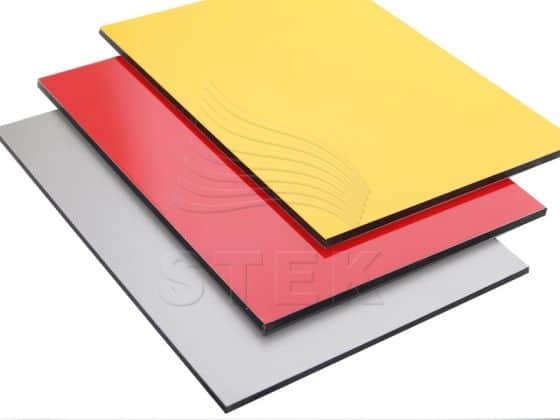

Aluminum composite panels consist of two thin aluminum sheets bonded to a non-aluminum core, typically made of polyethylene.

Importance of Bending Aluminum Composite Panels

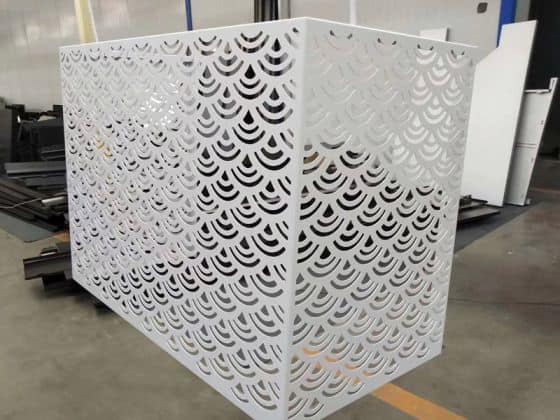

By shaping the panels to fit specific curves, angles, or geometries, you can create unique architectural elements that stand out. Bent ACPs can be used for curved facades, signage, furniture, and more, adding a touch of elegance and creativity to your projects

Methods of Bending Aluminum Composite Panels

There are several methods you can employ to bend aluminum composite panels. The choice of method depends on the complexity of the desired shape and the equipment available. Here are the most common methods:

Cold Bending

Cold bending involves manually bending the ACP sheets to the desired shape without applying heat. This method is suitable for simpler curves and angles. It requires careful handling to avoid damaging the panel’s surface.

Heat Bending

Heat bending utilizes controlled heat to soften the ACP and make it more pliable for shaping. This method is ideal for creating precise and complex curves. Heat can be applied using specialized heat guns or ovens.

V-grooving

V-grooving involves cutting V-shaped grooves on the backside of the ACP sheet at regular intervals. These grooves act as bending guides, allowing you to fold the panel along the grooves to achieve the desired shape. V-grooving is commonly used for creating crisp and clean bends.

Tools and Equipment Required for Bending

To successfully bend aluminum composite panels, you’ll need the following tools and equipment:

Heat Gun or Oven

If you choose to heat bend the ACPs, a heat gun or oven is necessary to apply controlled heat to the panel. Heat guns provide localized heating, while ovens offer more uniform heating for larger sheets.

V-Grooving Machine or Saw

For V-grooving, you’ll need a V-grooving machine or a saw with a specialized V-groove blade. These tools allow you to create the necessary grooves on the backside of the ACP sheet.

Clamps

Clamps are essential for securing the ACP sheet in place during the bending process. They ensure that the panel maintains its shape and prevents it from springing back.

Protective Gear

When working with ACPs, it’s crucial to prioritize safety. Wear appropriate protective gear, including gloves and safety glasses, to protect yourself from sharp edges, heat, and any potential debris.

Step-by-Step Guide to Bending Aluminum Composite Panels

Follow these step-by-step instructions to bend aluminum composite panels:

- Preparation: Gather all the necessary tools and equipment. Ensure you have a clear workspace and proper safety measures in place.

- Measure and Mark: Determine the dimensions and shape of the bend you want to create on the ACP sheet. Measure and mark the bend lines accurately.

- Cold Bending: If you’re cold bending, carefully apply pressure along the marked bend lines to shape the ACP sheet. Use clamps to hold the panel in place while bending.

- Heat Bending: If you’re heat bending, preheat the heat gun or oven to the recommended temperature. Apply heat evenly along the marked bend lines until the ACP becomes pliable. Use clamps to hold the panel in the desired shape until it cools down and retains its form.

- V-Grooving: If you’re using the V-grooving method, set up the V-grooving machine or attach the V-groove blade to the saw. Follow the manufacturer’s instructions to create V-grooves along the marked bend lines. Once the grooves are complete, carefully fold the panel along the grooves to achieve the desired shape.

- Finishing: Once the bending process is complete, inspect the panel for any imperfections or sharp edges. Use a file or sandpaper to smooth out any rough areas.

- Clean and Protect: Clean the bent ACP panel to remove any dirt or debris. Apply a protective coating or finish, if desired, to enhance durability and weather resistance.

Tips for Successful Bending

- To ensure successful bending of aluminum composite panels, consider the following tips:

- Practice on scrap pieces before bending the final panel to gain confidence and refine your technique.

- Use gentle and gradual force when cold bending to avoid damaging the panel’s surface.

- Apply heat evenly during heat bending to achieve uniform pliability and avoid overheating or warping.

- Maintain the desired shape of the bent panel by using clamps until it cools and sets.

STEK Aluminum: Your Trusted Source for Aluminum Composite Panels

At STEK Aluminum, we offer a wide range of ACP options in various sizes, colors, and finishes. Our panels undergo rigorous quality control measures to deliver exceptional products.

When it comes to high-quality aluminum composite panels for architectural decoration, STEK Aluminum is a trusted manufacturer and wholesale supplier. Our state-of-the-art manufacturing facility, coupled with our commitment to excellence, ensures that you receive top-notch ACP products that meet your design and performance requirements.