What is Aluminum Cladding?

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

Anodized aluminum is a process that enhances the natural oxide layer on the surface of aluminum, creating a durable and corrosion-resistant coating.

The anodizing process offers several benefits to aluminum. It increases the thickness and hardness of the oxide layer, making the aluminum more resistant to scratches, wear, and corrosion.

Anodized aluminum is commonly used in architectural applications, such as building facades, window frames, and decorative elements. It is also used in industries such as automotive, aerospace, and electronics, where corrosion resistance and aesthetic appeal are important.

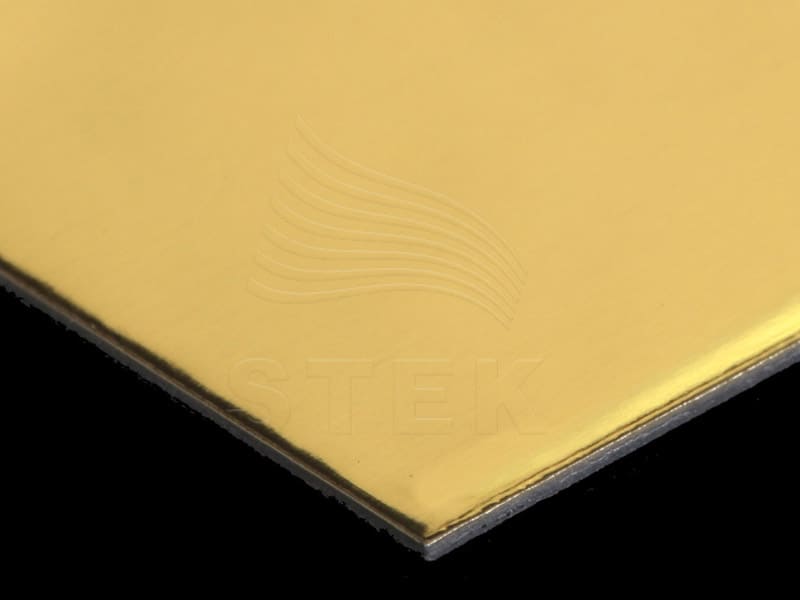

An anodized aluminum sheet refers to a flat sheet or panel made of aluminum that has undergone the anodizing process. It is a highly versatile and durable material used in architectural and industrial applications.

To create an anodized aluminum panel, the aluminum sheet is first treated to remove impurities and prepare the surface. Then, it is immersed in an electrolytic solution and an electric current is passed through it. This causes controlled oxidation of the aluminum, resulting in the formation of a thick and porous oxide layer on the surface.

An anodized aluminum sheets offers several advantages.

Anodized aluminum sheets find widespread use in commercial, residential, and institutional buildings. They are commonly employed for building facades, cladding systems, interior walls, signage, and decorative elements. These aluminum sheets offer a sleek and modern aesthetic while delivering long-lasting performance and design versatility.

At STEK Color Aluminum, we understand the importance of design flexibility. Our anodized aluminum sheet offer a wide range of customization options, including panel sizes, shapes, and color finishes.

To provide you with a comprehensive understanding of our anodized aluminum sheet, here are some key technical specifications:

Please note that these specifications can be tailored to meet the specific requirements of each project.

Anodized aluminum is a process that enhances the natural oxide layer on the surface of aluminum, creating a durable and corrosion-resistant coating. It increases the thickness and hardness of the oxide layer, making the aluminum more resistant to scratches, wear, and corrosion.

An anodized aluminum sheet has a protective oxide layer that regular aluminum lacks. This layer provides increased resistance to corrosion, weathering, and UV radiation, making the panel more durable and suitable for outdoor applications.

Absolutely. Anodized aluminum sheets are highly resistant to corrosion, making them an excellent choice for coastal applications.

Yes, anodized aluminum sheet are recyclable. Aluminum is a highly recyclable material, and the anodizing process does not affect its recyclability. Recycling aluminum helps conserve resources and reduce the environmental impact associated with extracting and manufacturing new aluminum.

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

Cleaning and maintaining powder coated aluminum panels is relatively simple. Here are some steps you can follow: clean powder coated aluminum panel Regular Cleaning: Use a mild detergent or soap mixed with wat...

Step-by-step instructions for bending aluminum composite panels, safety considerations, and tips for successful bending....

Looking for a reliable supplier for aluminum composite panels? Discover the advantages of aluminum composite panels, their various applications, factors to consider when purchasing, and find out where to buy th...