What is Aluminum Cladding?

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

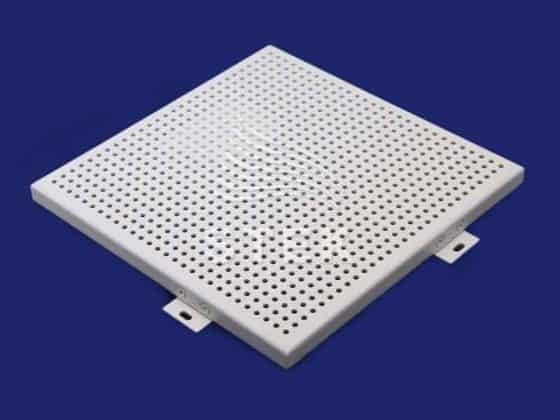

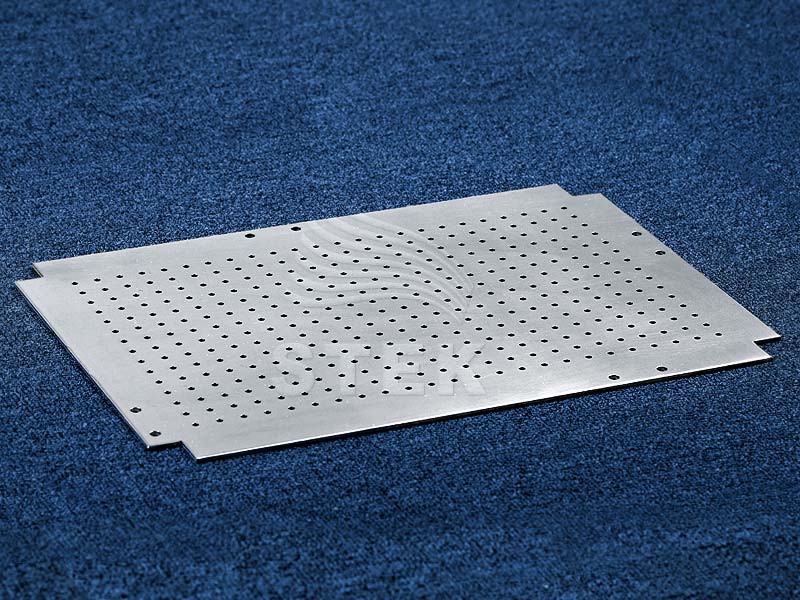

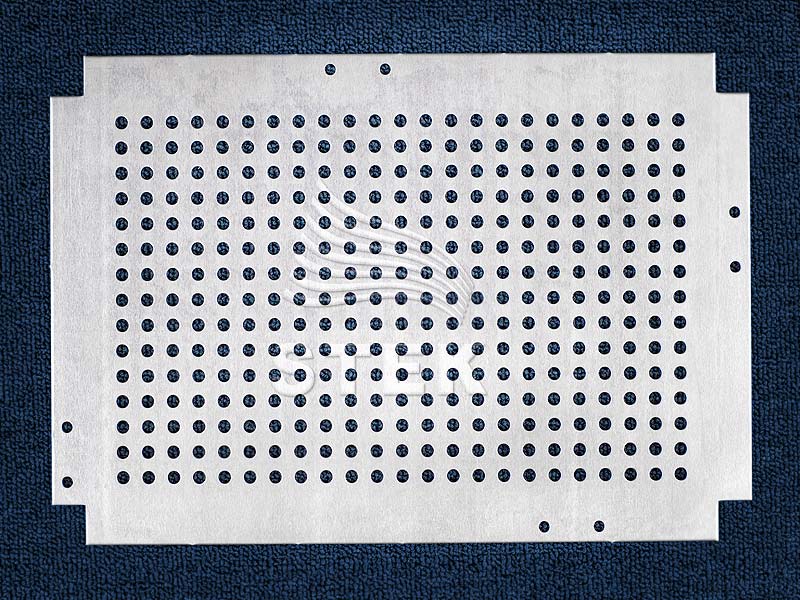

Through the calculation formula to calculate the punching force of the CNC tower pinching, so that painted perforated aluminium sheet maintains the maximum bearing capacity, and also solves the burr problem of the punching hole.the punching cut surface is rounded, and the service life is extended. Punching die of painted perforated aluminium sheet is made by high-quality steel. If the punching force is controlled well, there will be no burrs, which will maximize the bearing capacity of the punching panel and make the aluminum plate more durable. The punching force and punching gap required for 1mm, 2mm thick punching panels need to be accurately controlled then it can produce high-quality painted perforated aluminium sheet.

Aluminum base sheet range:

Thickness: 0.18mm-2.5mm

Commonly used width: 1000mm, 1200mm, 1250mm, other special widths can be according to customer requirements; common alloys: 1100, 3003, 3004, 8011, 3105, 5052, other alloys can be according to customer requirements.

We also produce Gray, iron gray, white gray, silver gray, dark gray, hemp pattern, imitation brick pattern, imitation copper, orange peel, crimson and other color coated aluminum coil products

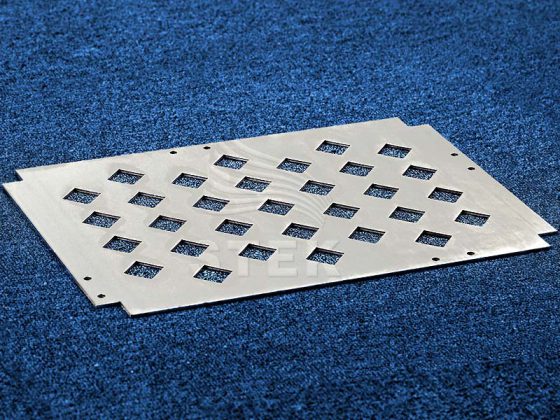

1. Material: a shearing machine cut the aluminum plate into square pieces, the diagonal size error is ±1mm;

2.Decoil: put the parts on a decoiler, during the self-inspection, the plate surface is required to be smooth;

3. Angle cutting: Place the flat square plate on the die cutting machine to perform corner forming to make the four corners symmetrical; p>

4. Punching: Place the square plate with cut corners on the touch tower punching machine;

5. Blanking: The formed square plate is formed by blanking, four sides internal angle ≤90%, four sides straight, so that the two square plates are seamlessly spliced;

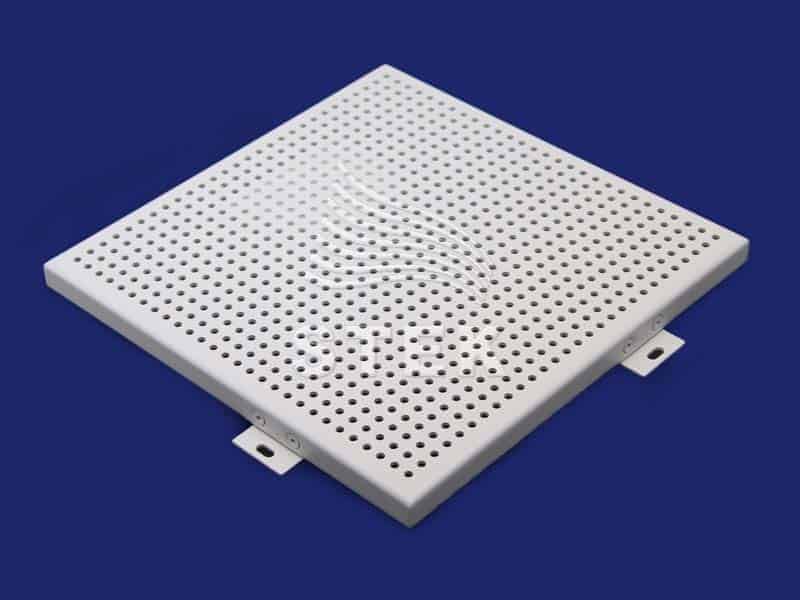

6. Spraying: to ensure that the product has no color difference, no defects, and good leveling;

7. inspection :According to the process 4-5;

8. Packing: according to customer requirements, shipping!

painted perforated aluminium sheet also has many characteristics, such as high strength, anti-fading, fingerprint resistant, antistatic, self-cleaning, thermal insulation and corrosion protection, fingerprint resistant, high weather resistance etc.

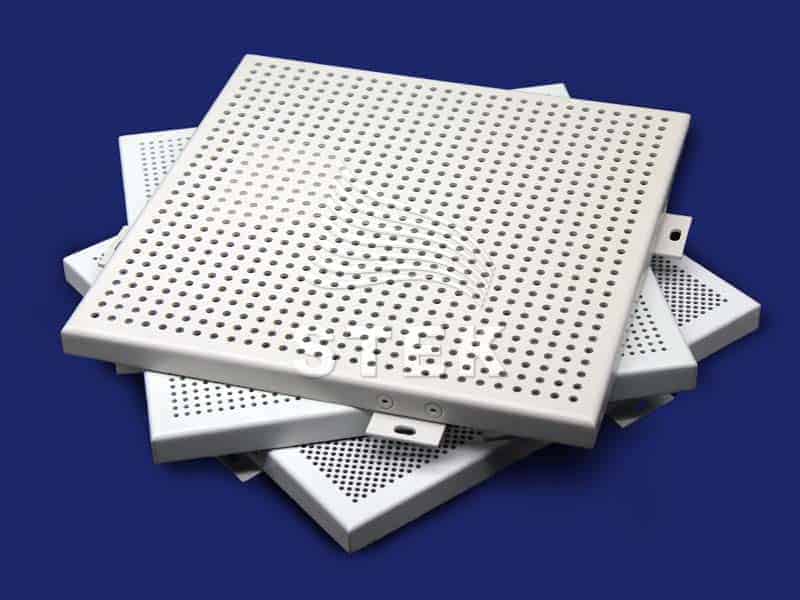

a) Outdoor use: codenamed W;

b) Indoor use: The code is N.

painted perforated aluminium sheet can also be used to make wood look aluminium fence, painted aluminium sheet for trailers, perforated aluminium fence panels, painted aluminium gutters, aluminium decking etc.

With high-grade aluminum alloy as the main material, according to the design size, shape and construction form of the project site to ensure that the plate can be smooth and not deformed after processing.

Average film thickness is the arithmetic average of several (not less than five) local film thickness values measured on the decorative surface of the aluminum plate.

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

Painting aluminum siding allows for customization and provides an additional layer of corrosion protection. By choosing the right paint and seeking professional assistance, following the steps outlined in this ...

Cleaning and maintaining powder coated aluminum panels is relatively simple. Here are some steps you can follow: clean powder coated aluminum panel Regular Cleaning: Use a mild detergent or soap mixed with wat...

Step-by-step instructions for bending aluminum composite panels, safety considerations, and tips for successful bending....

Looking for a reliable supplier for aluminum composite panels? Discover the advantages of aluminum composite panels, their various applications, factors to consider when purchasing, and find out where to buy th...