What is Aluminum Cladding?

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

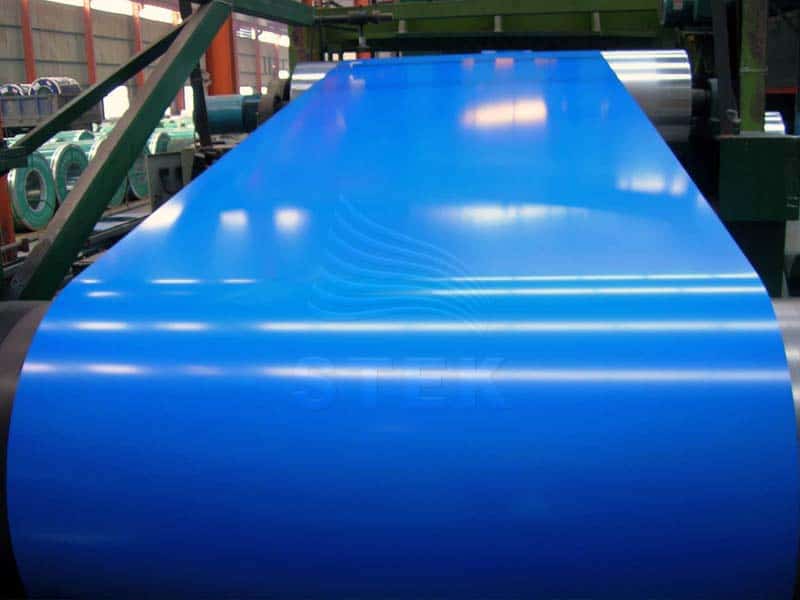

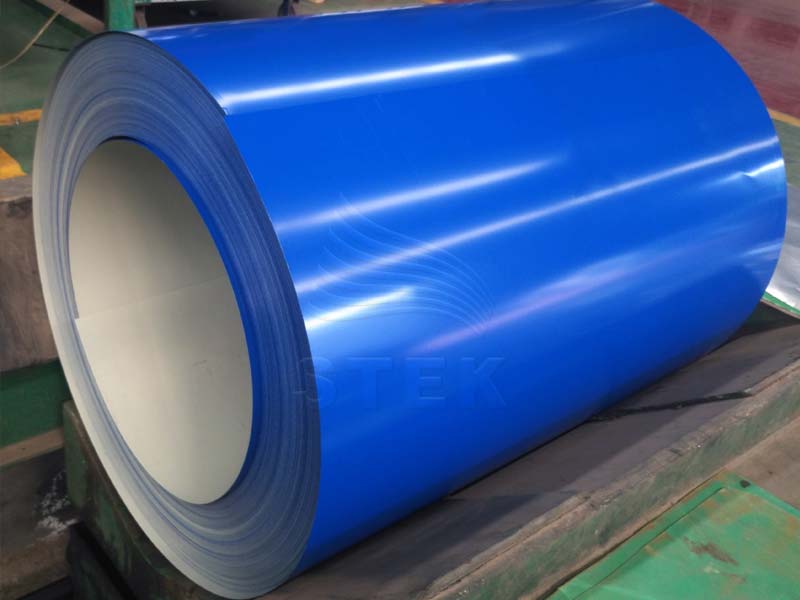

solid color aluminum coilis made of high-quality aluminum alloy material after de-esterification, cleaning and passivation layer processing.

On this basis, rollers coating with various colors of fluorocarbon PVDF, to make the aluminum plate durable; this is the great difference color coating Aluminum coils from aluminized and galvanized solid color aluminum coilin quality.

STEK Color Aluminum is a professional manufacturer of color-coated aluminum coils, which can provide the price and information of solid color aluminum coilon that day. You can also contact our local agents and distributors for discounts.

All products are sold by the factory directly, the wholesale price is low, and the quality fulfill the requirements of the national standard.

solid color aluminum coilprovides personalized exterior wall and ceiling color spaces for architects, designers and owners. and is also an ideal material for architectural modeling. Whether it is used for multi-functional large-scale building or unique and innovative new building.

solid color aluminum coilcan always fulfill the different requirements of modern and classic architectural styles and make the building colorful . The products have been applied in many fields such as electronic appliances, instrumentation, lighting, packaging, home decoration and so on.

Acrylic coating is a coating formed by curing acrylic resin-based paint on the metal surface.

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

In today’s society, solid color aluminum coilcan be seen in almost all fields. When buying, customers must keep your eyes open, choose the product that suits you, learn more about the solid color aluminum coil, and welcome to pay attention to the company’s trends.

If one item of acid resistance and mortar resistance is unqualified in the type inspection results, the batch of products shall be judged as unqualified. If one of the other items is unqualified, the unqualified products can be sampled and re-inspected.

When the re-inspection results all meet the standard requirements, the batch of products will be deemed qualified, otherwise the batch of products will be deemed unqualified.

The production, transportation and storage of solid color aluminum coilall need to our employees and users to try it out as required. Many people think that their products will have problems quickly after used, which is a quality issue. In fact, except quality problems, it may also be ignored in a daily protection, so we need reasonable storage and transportation.

solid color aluminum coilis a new type of decorative material, which have a wide usage and can be recycled. The fluorocarbon coating has many advantages such as self-cleaning, high strength, high durability, anti-fading, fingerprint resistant, high weather resistance, self-cleaning. It is the first choice material for replacing galvanized color coated coil.

The product quality exceeds national standards and the factory wholesale price; and we also produce Green, dark green, light bean green, imitation brick pattern, orange peel, camouflage pattern and other color-coated aluminum sheet and coil, please contact us to get the accurate price of solid color aluminum coil!

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

Painting aluminum siding allows for customization and provides an additional layer of corrosion protection. By choosing the right paint and seeking professional assistance, following the steps outlined in this ...

Cleaning and maintaining powder coated aluminum panels is relatively simple. Here are some steps you can follow: clean powder coated aluminum panel Regular Cleaning: Use a mild detergent or soap mixed with wat...

Step-by-step instructions for bending aluminum composite panels, safety considerations, and tips for successful bending....

Looking for a reliable supplier for aluminum composite panels? Discover the advantages of aluminum composite panels, their various applications, factors to consider when purchasing, and find out where to buy th...

Learn our tips and methods for cleaning aluminum cladding for a clean, beautiful, spotless finish....

Learn how to attach aluminum cladding to a steel frame in this informative guide. Follow our step-by-step instructions and improve the look and protection of your building....

Are you considering installing aluminum cladding to your home\'s exterior trim? Aluminum cladding is a durable and low-maintenance material that can protect your trim from weather damage and give your home an u...