What is Aluminum Cladding?

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

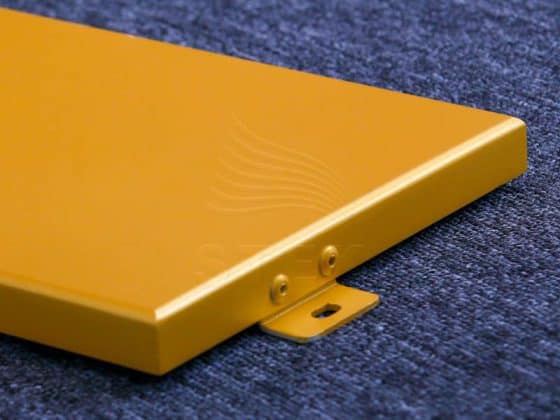

The aluminum panel for curtain wall is made of high-strength aluminum alloy sheet and processed by fluorocarbon paint. Its high-strength corrosion resistance, weather resistance, acid rain and various pollutants are all very good , which all are suitable for building decoration materials.

| size of base plate | thickness | 0.2-1.5mm |

| width | 600-1850mm | |

| thickness of coating | single coated | 4-20μm |

| double coated | 25-28μm | |

| three coated | 35-38μm | |

| colors | Refer to the color chart of our company, and also can modulate any color according to customer needs | |

1. Light weight, good rigidity and high strength. The weight of thickness 3.0mm aluminum plate is 8kg per square and has a tensile strength of 100-280n/mm2.

2.Good durability and corrosion resistance. PVDF fluorocarbon paint based on kynar-500 and hylur500 can be used for 25 years without fading. good corrosion resistance, color and gloss retention , make it long life and lasting as new.

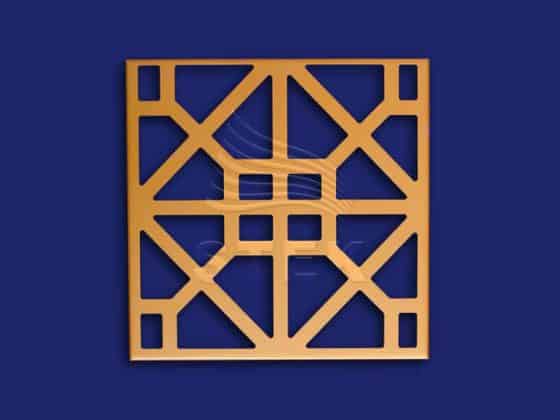

3. Good craftsmanship. By adopting the process first and then spraying,the aluminum plate can be processed into a variety of complex geometric shapes such as plane, arc and spherical surface.

4. Uniform coating and diverse colors. The advanced electrostatic spraying technology makes the adhesion uniform between the paint and the aluminum plate, the coating surface is smooth and smooth, and the color is uniform and bright; while ensuring the continuity and consistency of color, the diversity of color makes it a large choice.

5. Rich types of coatings. Polyester, polyurethane, fluorocarbon, laminating and other coatings are available to meet special needs.

6.Not easy to stain, easy to clean and maintain.

The non-adhesiveness of the fluorine coating film makes surface difficult for contaminants to adhere, and has good cleanliness. Mingzhu’s self-cleaning aluminum sheets solve the problem of high difficulty cleaning for outdoor curtain walls aluminum panels.

7. Convenient and quick installation and construction. The aluminum plate is formed in the factory and does not need to be cut at the construction site, just fixed on the frame.

8. It can be recycled and reused, which is good for environmental protection. Aluminum plates can be recycled 100%, which is different from decorative materials such as glass, stone, ceramics, and aluminum-plastic panels, with a high recycling rate.

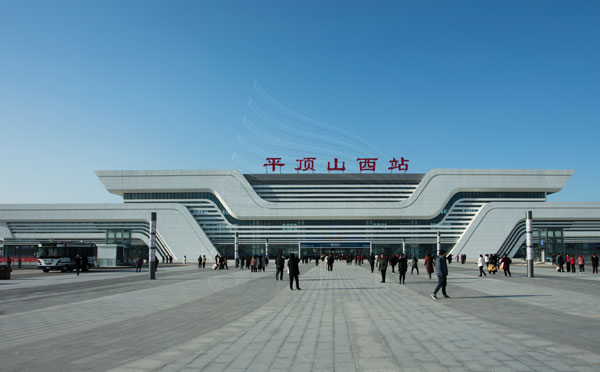

Aluminum panels for curtain wall is a new type of curtain wall material,which uses high-quality aluminum alloy sheets as the base material,then be formed by CNC bending and other technologies, and the surface is sprayed with decorative coatings.Nowadays, most buildings use this kind of material for exterior wall or interior decoration. The sheet has a long durability and a very high recycling rate. It can be called an environmentally friendly green building material, and it is very suitable for various buildings.

Color coated aluminium solid panel It has the advantages of both aluminum plate and organic material. It not only has the advantages of high mechanical strength, good toughness, and easy processing and forming of aluminum plate, but also has good coloring, decorative, and decorative properties of organic polymer coating materials.

Corrosion resistance, it can be easily processed by punching, bending, deep drawing, welding, etc. The products made by aluminium are practical, decorative, easy to process and durable. The adhesion between the printed layer and the bottom layer is high.

Our factory chooses high-quality fluorocarbon coatings from the world-renowned fluorocarbon coating manufacturers PPG, AKZO Akzo and other companies. The color selection is wide. Customers can directly select or provide color samples according to the color plates provided by the manufacturers.

Use distilled water to prepare a 10% (volume ratio) hydrochloric acid solution (prepared with 37% industrial grade hydrochloric acid), and drop 10 drops on the paint film and cover it with an observation glass, with the convex surface facing up, take off the glass after 15 minutes, rinse with tap water, and check after drying.

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two layers Min 23μm | ≥25μm |

| Three layers Min 30μm | ≥34μm | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥50kg.cm | ≥50kg.cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h No change | 4h No change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paints remaining | 500 times no break |

| 10 | Acidity Resistance | ASTM D1308 | 5%HCL 24hrs No change | No change |

| 11 | Alkali Resistance | ASTM D1308 | 5%NaOH 24hrs No change color △E≤2.0 | No change |

| 12 | Nitric acid Resistance | AAMA620 | △E≤5.0 | △E≤5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20#oil 24hrs No change | No change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs ≤Grade 1 | No change |

| 15 | Abrasion resistance | ASTM D968 | ≥5L/μm | ≥5L/μm |

| 16 | Dirt Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color retaining | GB/T16259 | 4000 hrs△E≤4.0 | 4000 hrs △E≤3.0 |

| 18 | Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 | |

| 19 | Chalking | 4000 hrs No change | 4000 hrs No change |

Aluminum cladding is a type of exterior wall cladding made from aluminum sheets. ...

Cleaning and maintaining powder coated aluminum panels is relatively simple. Here are some steps you can follow: clean powder coated aluminum panel Regular Cleaning: Use a mild detergent or soap mixed with wat...

Step-by-step instructions for bending aluminum composite panels, safety considerations, and tips for successful bending....

Looking for a reliable supplier for aluminum composite panels? Discover the advantages of aluminum composite panels, their various applications, factors to consider when purchasing, and find out where to buy th...